We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

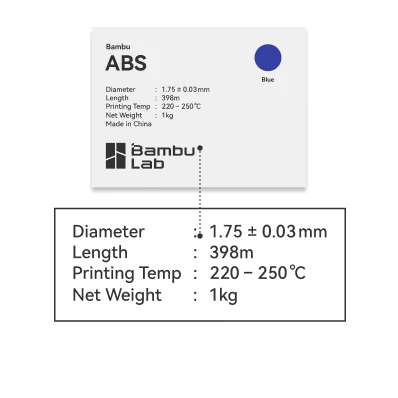

ABS

Printing Tips

- Pungent and unpleasant odors may be released during printing. Make sure your printer is placed in a well-ventilated area.

- Recommended to dry out before use to get higher printing quality and the recommended drying condition is 80 ℃ for 8 hours in a blast drying oven, or 100 ℃ for 12 hours on a printer's heatbed.

- ABS is prone to warping when printing large size and/or high infill density model. To avoid warping: 1) Not recommemded to print too large size and/or high infill density model. 2) Use enclosure printers and ensure the build plate is properly glued before printing. 3) Set lower printing speed and higher heatbed temperature.

-

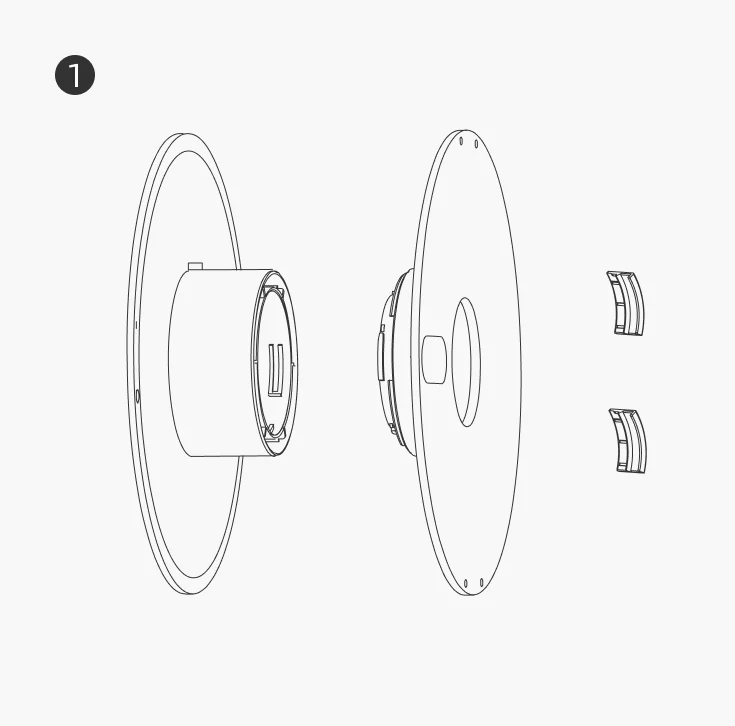

When you're finished printing, you will have a wide piece (1x), narrow piece (1x), spacing shim (2x).

-

-

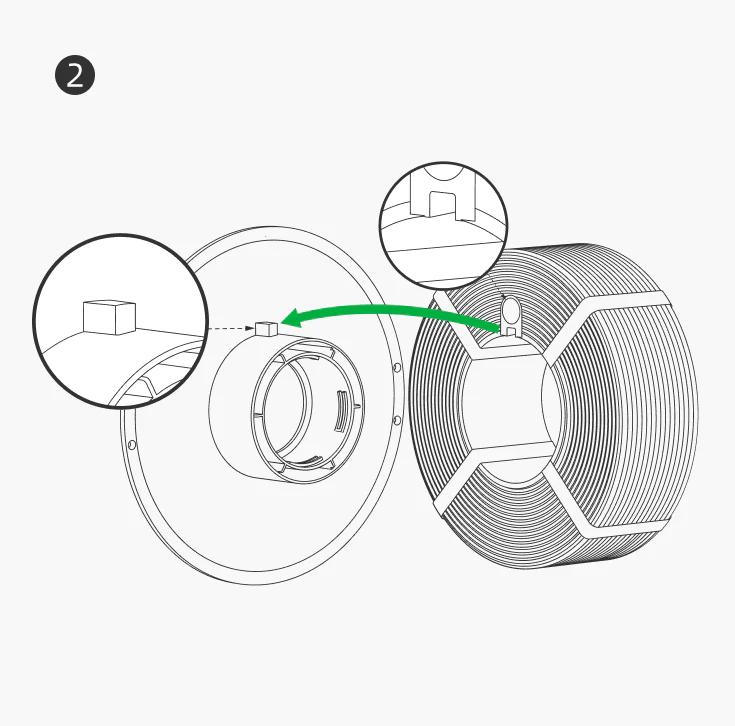

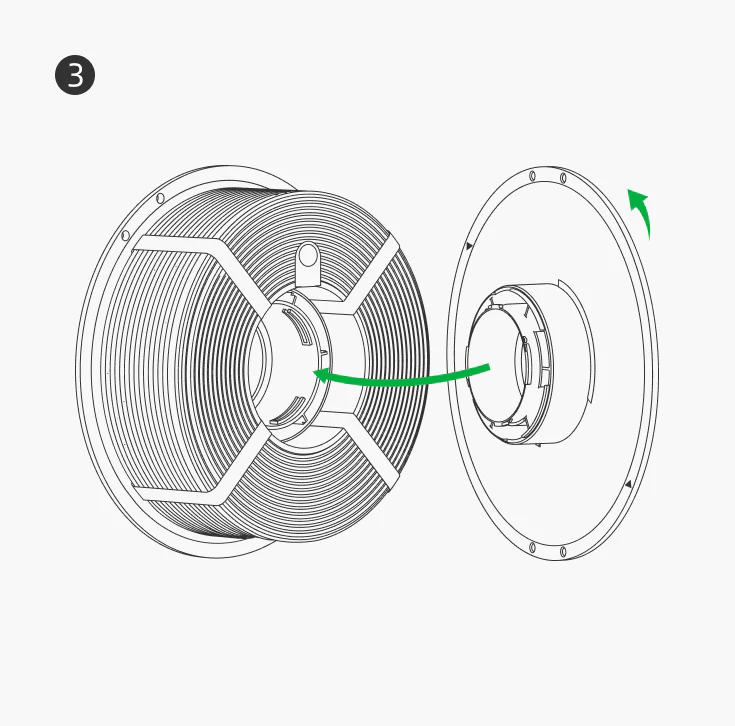

Find the locator (a tiny block on the wide piece). Align it with the notch on the inner ring of the filament roll. Insert the wide piece into the filament roll.

-

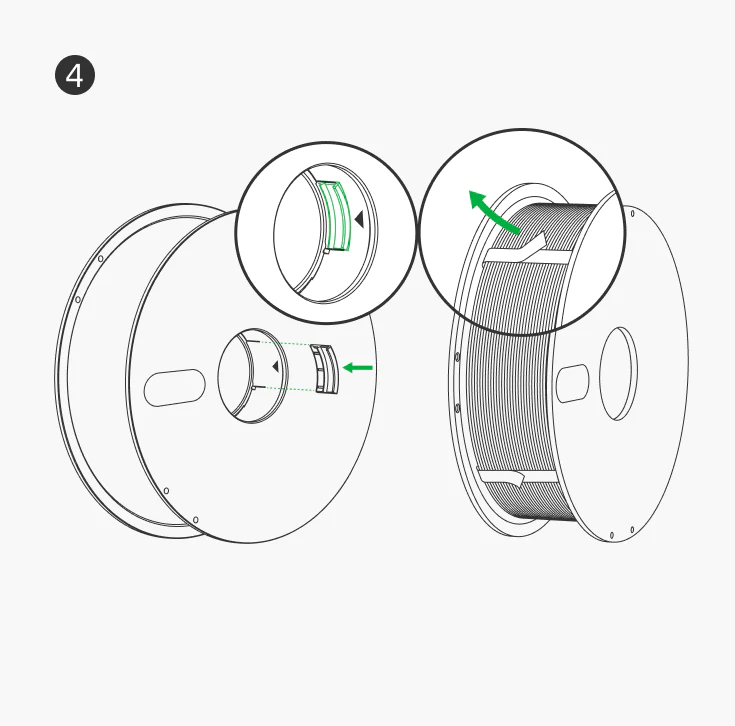

Step 1. Insert the narrow piece and align the groove of each piece inside of the spool until it is pushed firmly into the wide piece.

Step 2. Once it is pushed firmly into the wide piece, rotate the narrow piece clockwise until it slides into place and you hear it lock. -

Step 1. Make sure the spacing shim is installed inside the spool (under the triangle).

Step 2. Tear apart and pull out the plastic strips.

| Drying Settings (Blast Drying Oven) | 80 °C,8 h |

| Printing and Keeping Container's Humidity | < 20% RH (Sealed,with Desiccant) |

| Nozzle Temperature | 240 - 270 °C |

| Bed Temperature (with Glue) | 80 - 100 °C |

| Printing Speed | < 300 mm/s |

| Melting Temperature | 200 °C |

| Density | 1.05 g/cm³ |

| Impact Strength | 39 ± 3.6 kJ/m² |

Related items you may like

Customer Reviews

of customers recommend this product