We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Bambu Lab X1 Carbon Combo Education Bundle with 2-Year Warranty

-

What to Expect from the X1-Carbon 3D Printer

What to Expect from the X1-Carbon 3D Printer

1. 20 m/s² acceleration

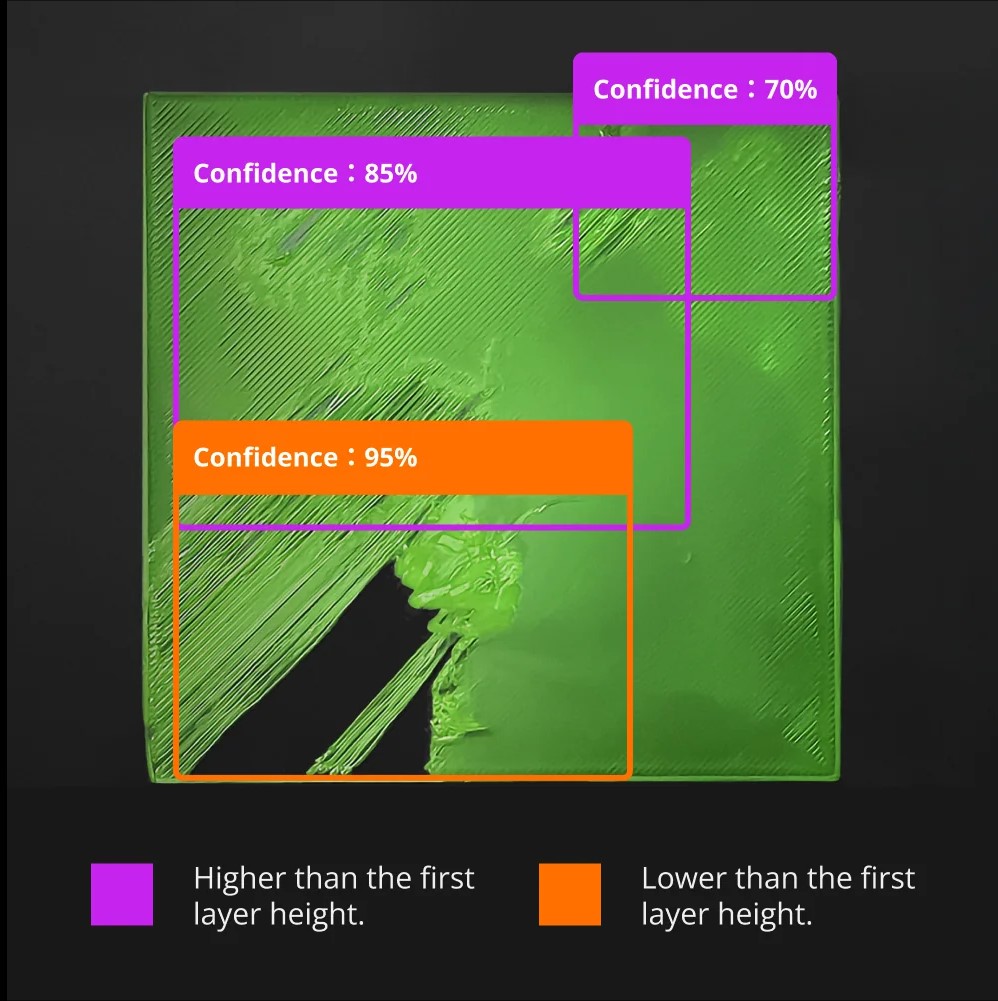

2. Micro lidar assisted bed leveling

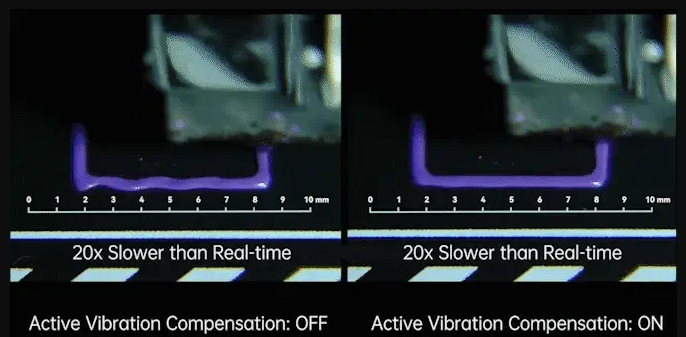

3. Active vibration compensation for better print quality

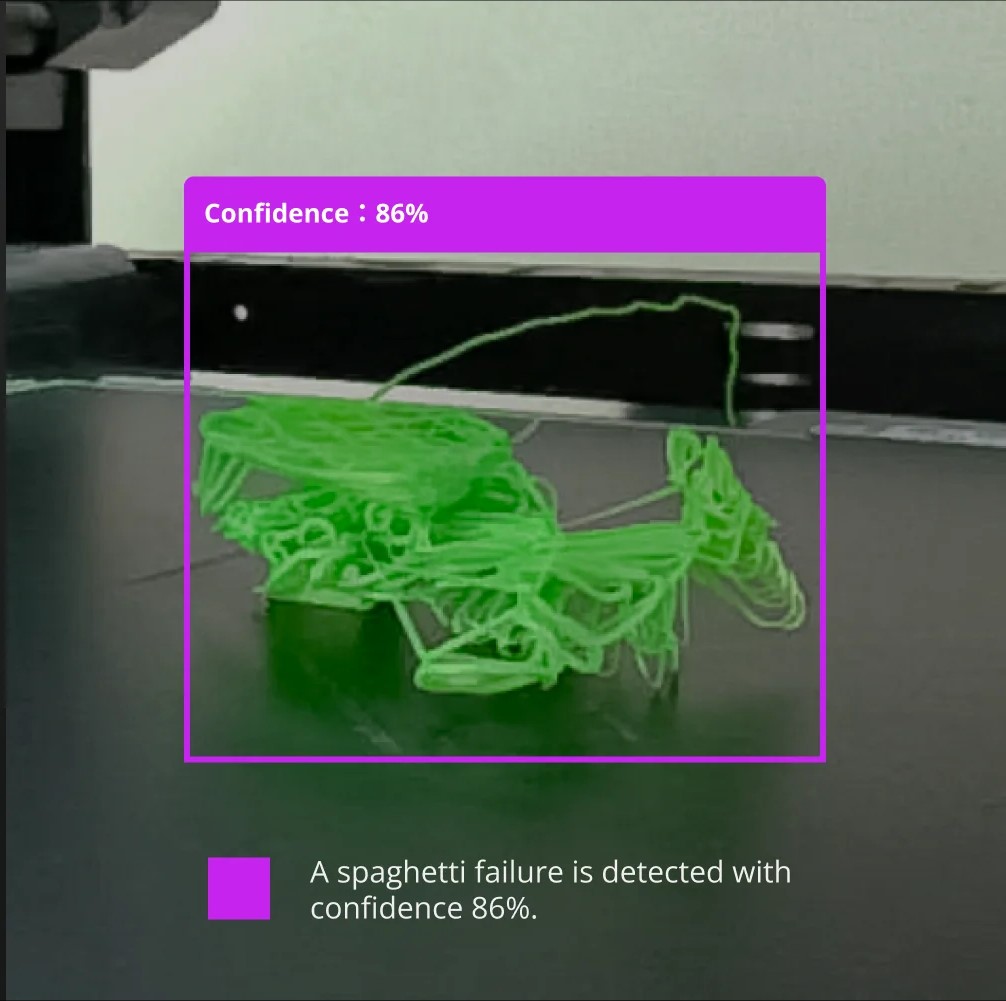

4. Spaghetti failure detection and auto-pause

5. Print resume after power outage

-

Colors & Beyond

Colors & Beyond

With Bambu Lab Automatic Material System (AMS),you can now enjoy printing freely in multiple colors and materials.

-

-

Vibration Compensation & Extrusion Compensation

Vibration Compensation & Extrusion Compensation

The active vibration compensation (XY) algorithm and extrusion compensation guarantees extra smoothness and gets you good prints.

-

New-user Friendly & Easy to Print

New-user Friendly & Easy to Print

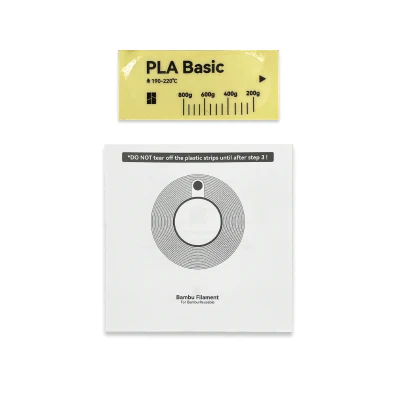

Bambu PLA Basic is designed to be extremely user-friendly, making it an ideal choice for beginners or those new to 3D printing. What’s more, PLA Basic enables users to achieve high-quality prints consistently, without the need for extensive adjustments or advanced printing settings.

-

High-printing Quality

High-printing Quality

Bambu Lab's PLA filament stands out for its high print speed, and excellent appearance. Experience the benefits of smooth and flawless prints with superior quality that exceeds expectations.

-

RFID for Intelligent Printing

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System). Load and print! No more tedious setting steps.

-

-

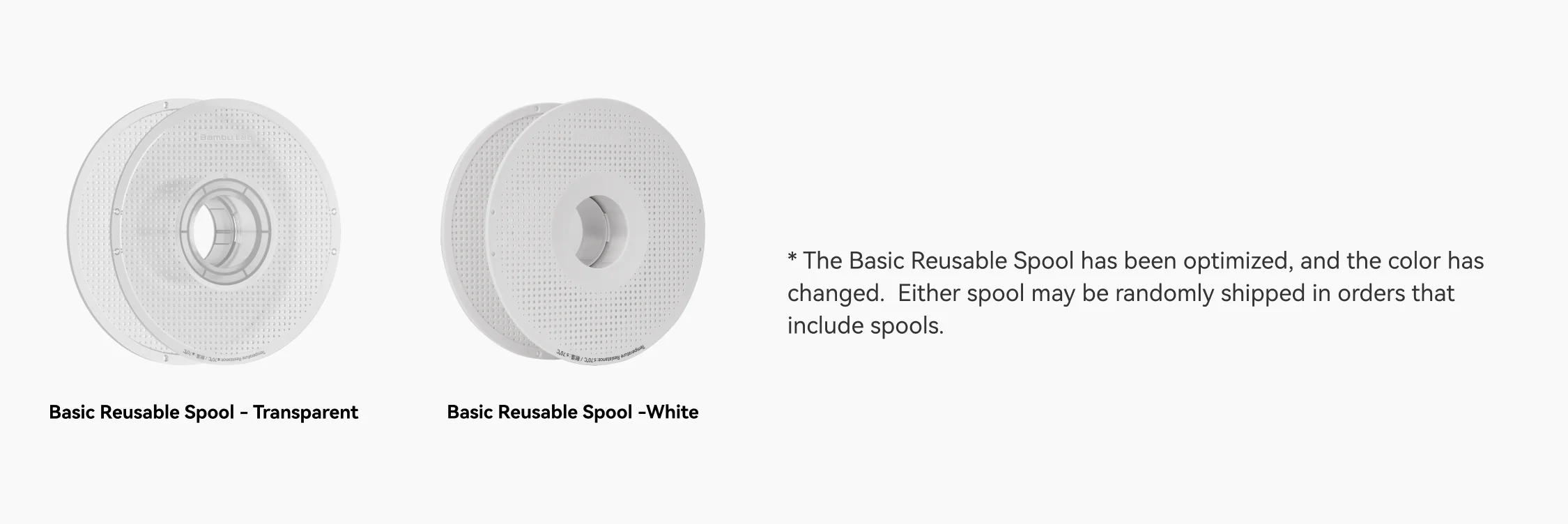

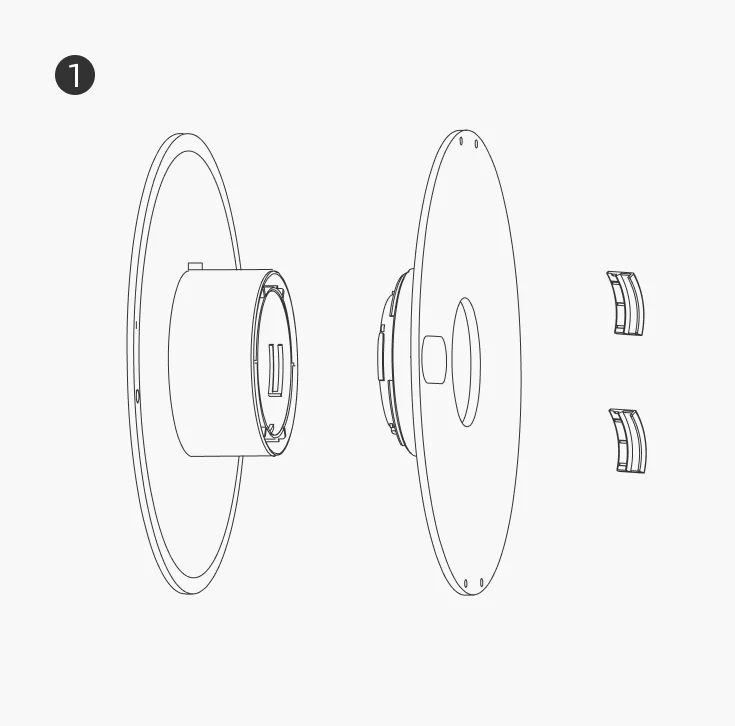

When you're finished printing, you will have a wide piece (1x), narrow piece (1x), spacing shim (2x).

-

Find the locator (a tiny block on the wide piece). Align it with the notch on the inner ring of the filament roll. Insert the wide piece into the filament roll.

-

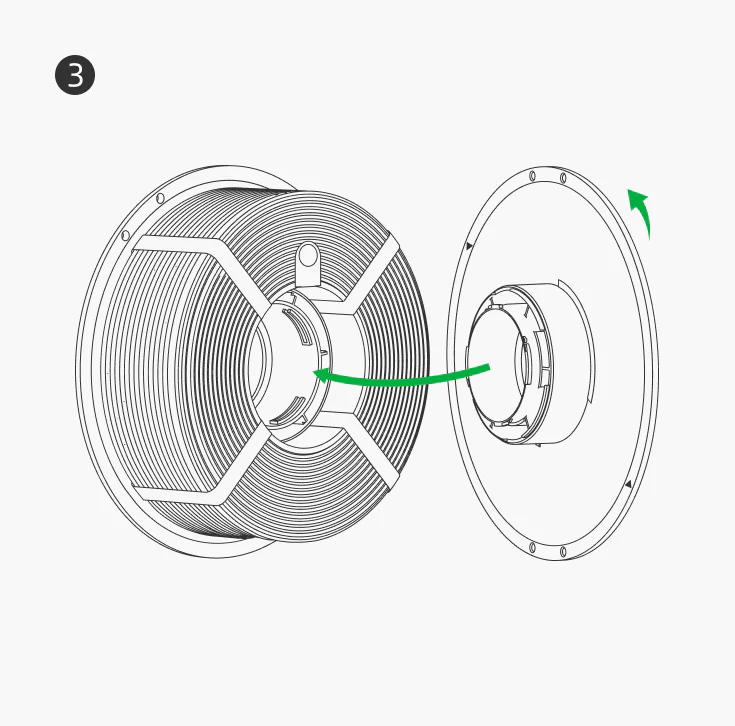

Step 1. Insert the narrow piece and align the groove of each piece inside of the spool until it is pushed firmly into the wide piece.

Step 2. Once it is pushed firmly into the wide piece, rotate the narrow piece clockwise until it slides into place and you hear it lock.

-

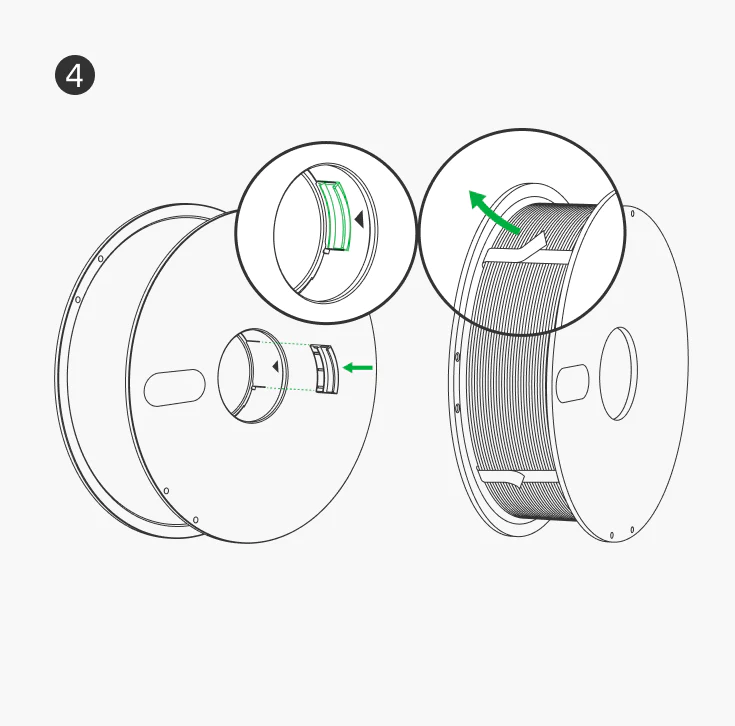

Step 1. Make sure the spacing shim is installed inside the spool (under the triangle).

Step 2. Tear apart and pull out the plastic strips.

| Name | X1 Carbon 3D Printer |

| Build Volume(W*D*H) | 256 × 256 × 256 mm³ |

| Nozzle | 0.4 mm Hardened Steel Included |

| Hotend | All-Metal |

| Max Hot End Temperature | 300 ℃ |

| Filament Diameter | 1.75 mm |

| Supported Filament | PLA, PETG, TPU, ABS, ASA, PVA, PET Ideal for PA, PC, Carbon/ Glass Fiber Reinforced Polymer |

| Build Plate Surface | Bambu Cool Plate, Bambu Engineering Plate Included |

| Max Build Plate Temperature | 110℃@220V, 120℃@110V |

| Max Speed of Tool Head | 500 mm/s |

| Max Acceleration of Tool Head | 20 m/s² |

| Physical Dimensions | 389 × 389 × 457 mm, Net weight 14.13 kg, Gross weight 18 kg |

| Electrical Requirements | 100-240 VAC, 50/60 Hz, 1000W@220V, 350W@110V |

Customer Reviews

of customers recommend this product