We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

H2C Laser Full Combo

Product Features

- Hotend Change Multi-material Printing

- Minimal Purge Waste Multi-Color Printing

- Precise & Fast Inductive Nozzle Heating

- Close-loop Servo Extruder

- Full Filament Path AI Error Detection

- 350°C Nozzles & 65°C Active Heated Chamber

- Optional 10W/40W Laser and Cutting Module

- 330*320*325 mm³ Build Volume

How You Print Your Projects

-

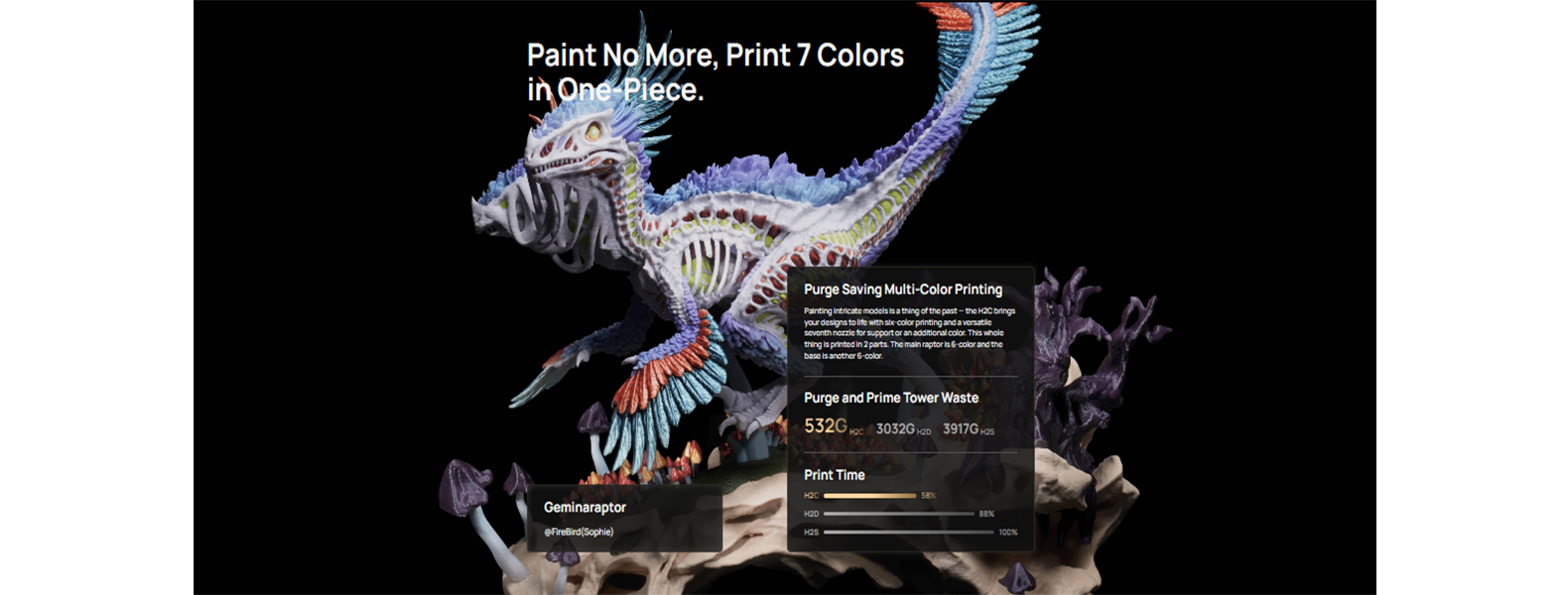

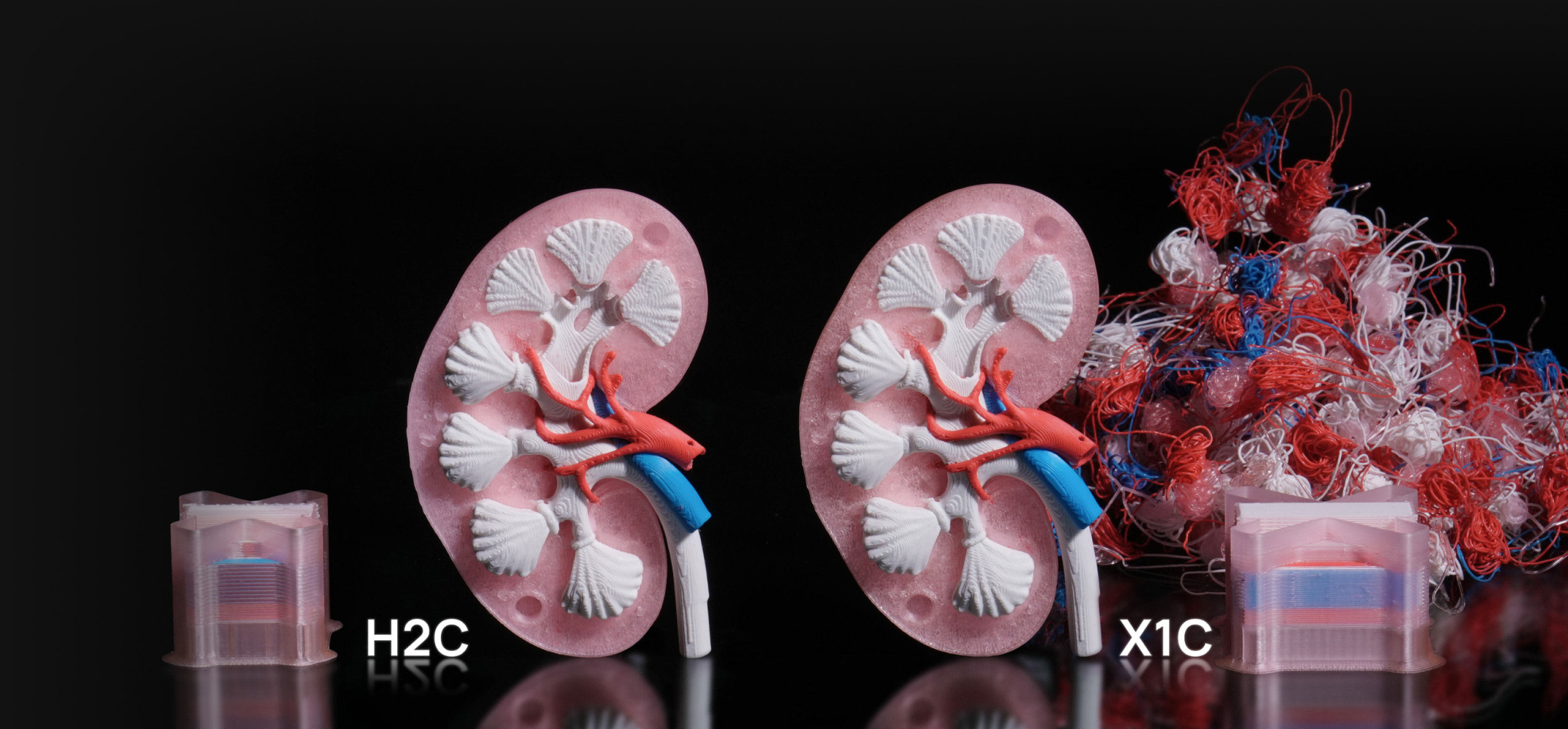

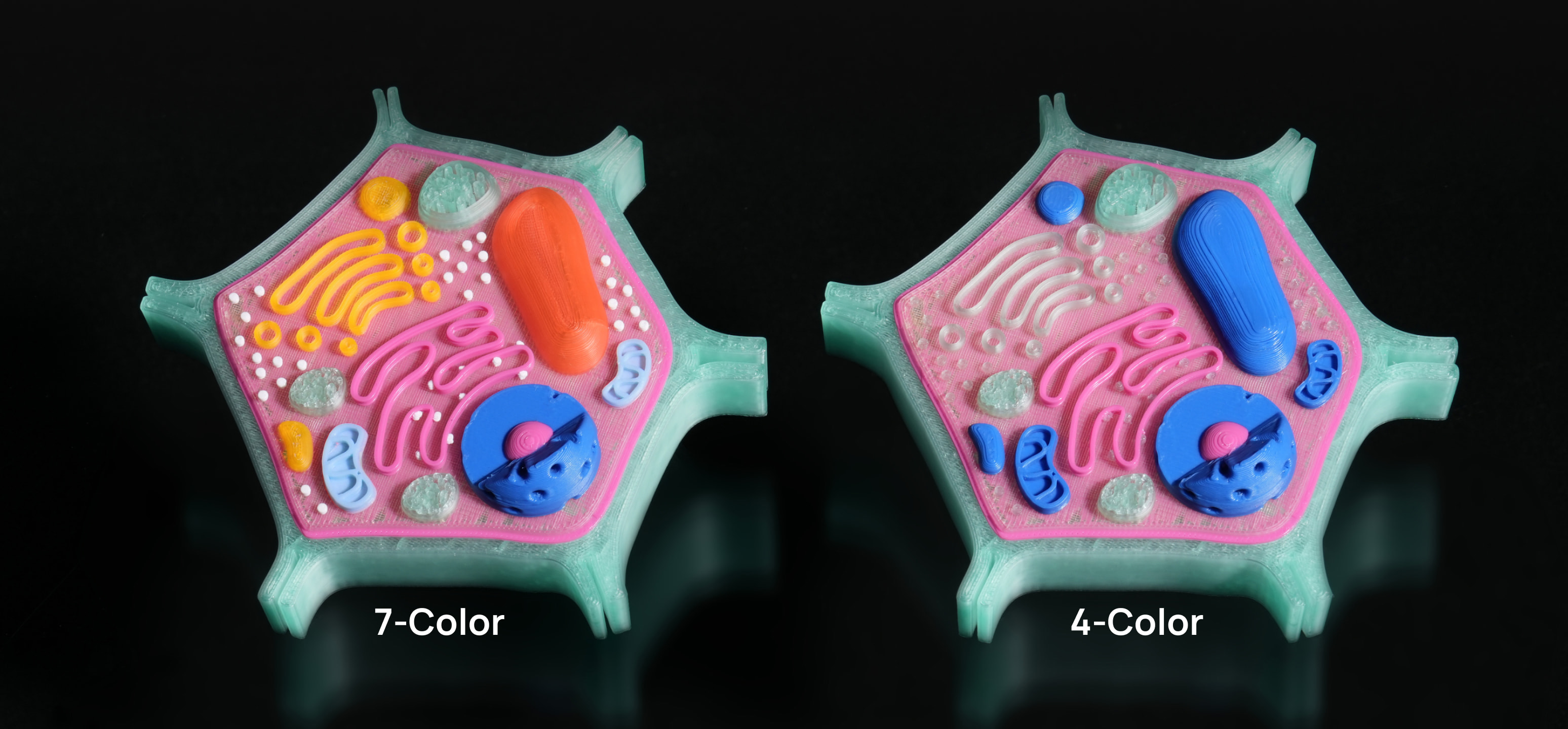

Multi-Material Printing with Minimal Purge Waste

Multi-Material Printing with Minimal Purge WasteIn traditional single-nozzle multi-material printing, purging is needed to clear leftover material between filament changes.Vortek changes that with an intelligent hotend-swapping system that replaces the entire hotend — delivering faster, cleaner prints with minimal waste.

-

Fully Automatic Filament Change

Fully Automatic Filament ChangeThe Vortek system works seamlessly with our highly reliable AMS (Automatic Material System), making the entire filament change process fully automatic — no need to manually load each filament into the toolhead.

-

Always Delivering the Most Efficient Combination

Always Delivering the Most Efficient CombinationWith less than 1mm writing accuracy and writing height, all interactive functions can be operated within several ms, bringing smoother learning and working experience.

Common application scenarios are classrooms, commercial offices, medical facilities, etc.

-

-

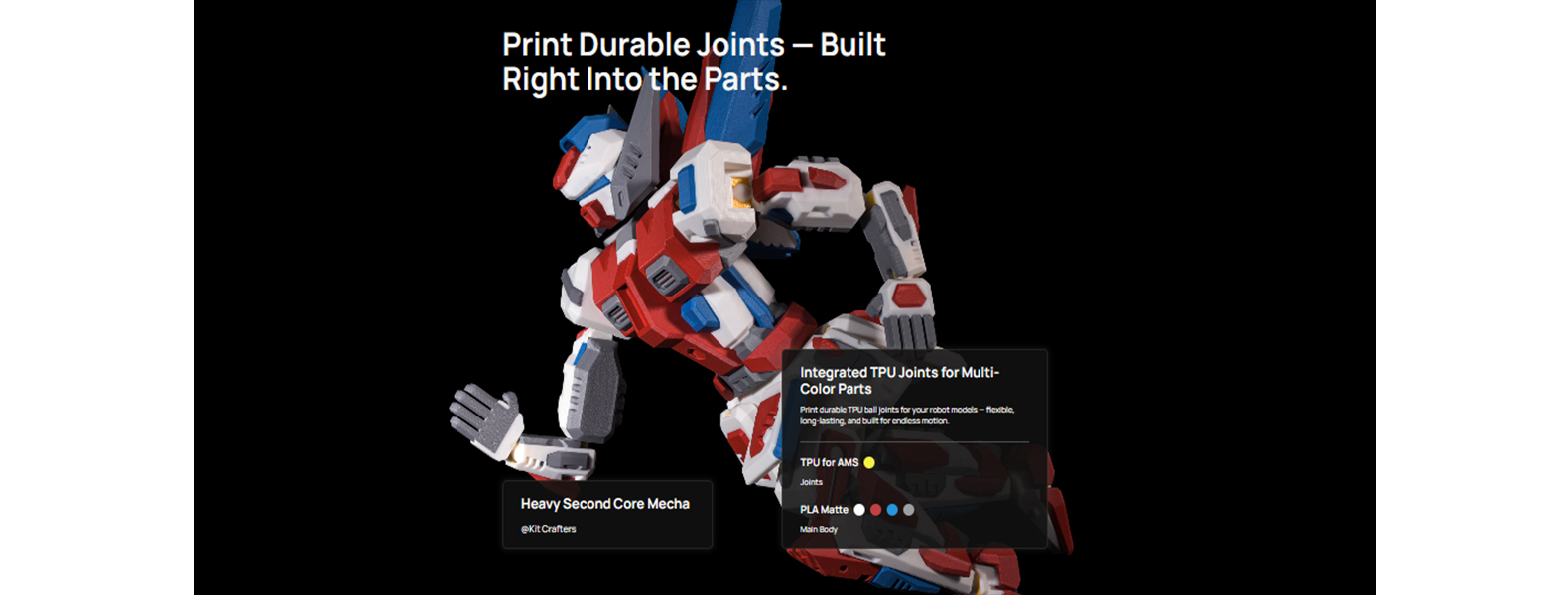

Small Form Factor, More Filaments

Small Form Factor, More FilamentsBecause only the hotend is swapped, the system can house up to six replaceable hotends without significantly reducing the build volume.That means more materials, more colors, and more possibilities — all in one print.

-

8-Second Induction Heating

8-Second Induction HeatingOur industry-leading induction heating technology brings the nozzle to temperature in 8-sec, significantly reducing the preheating time for each material swap compared to traditional methods.

-

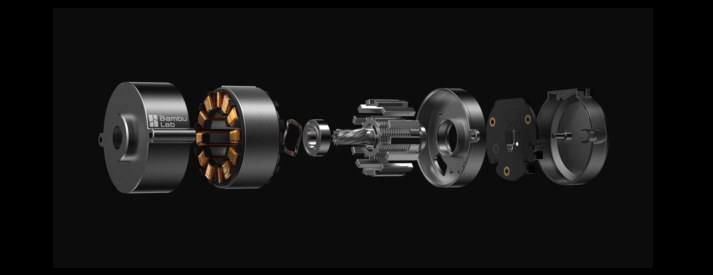

Contactless Design For Reliability

Contactless Design For ReliabilityOur high standards for reliability led us to move away from contact-based metal pins, which are prone to oxidation and unstable connections.We developed a contactless solution that ensures a stable, high-frequency connection — the foundation for precise temperature control and intelligent hotend sync.

-

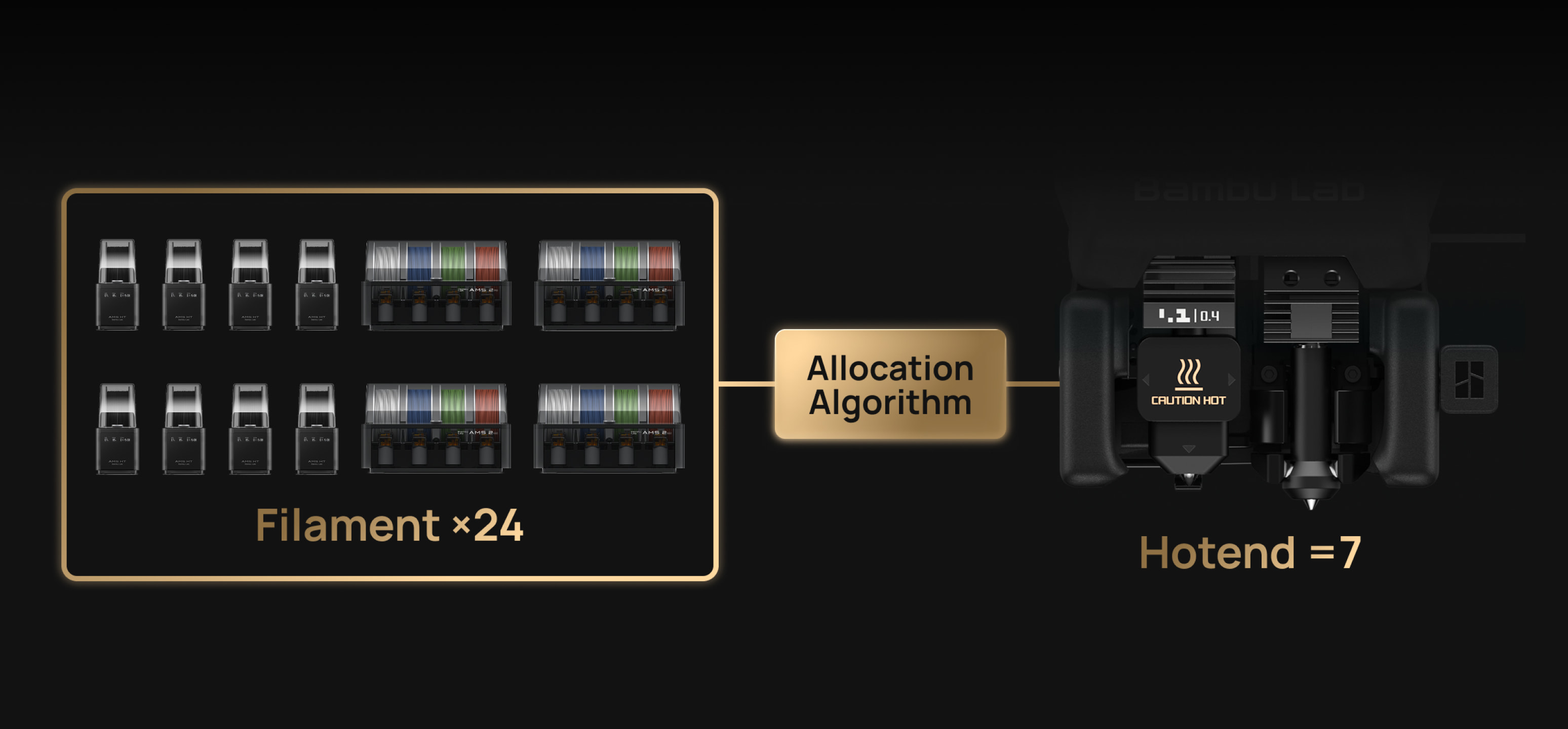

Colors Are No Longer Limited By How Many Toolheads You Have

Colors Are No Longer Limited By How Many Toolheads You HaveUnlike traditional toolchanger printers that limit color count by the number of toolheads, the H2C supports up to 24 materials in a single print through parallel-connected AMS units. Its intelligent algorithm optimizes filament-to-hotend allocation to minimize purge waste while delivering outstanding multi-color and multi-material results.

-

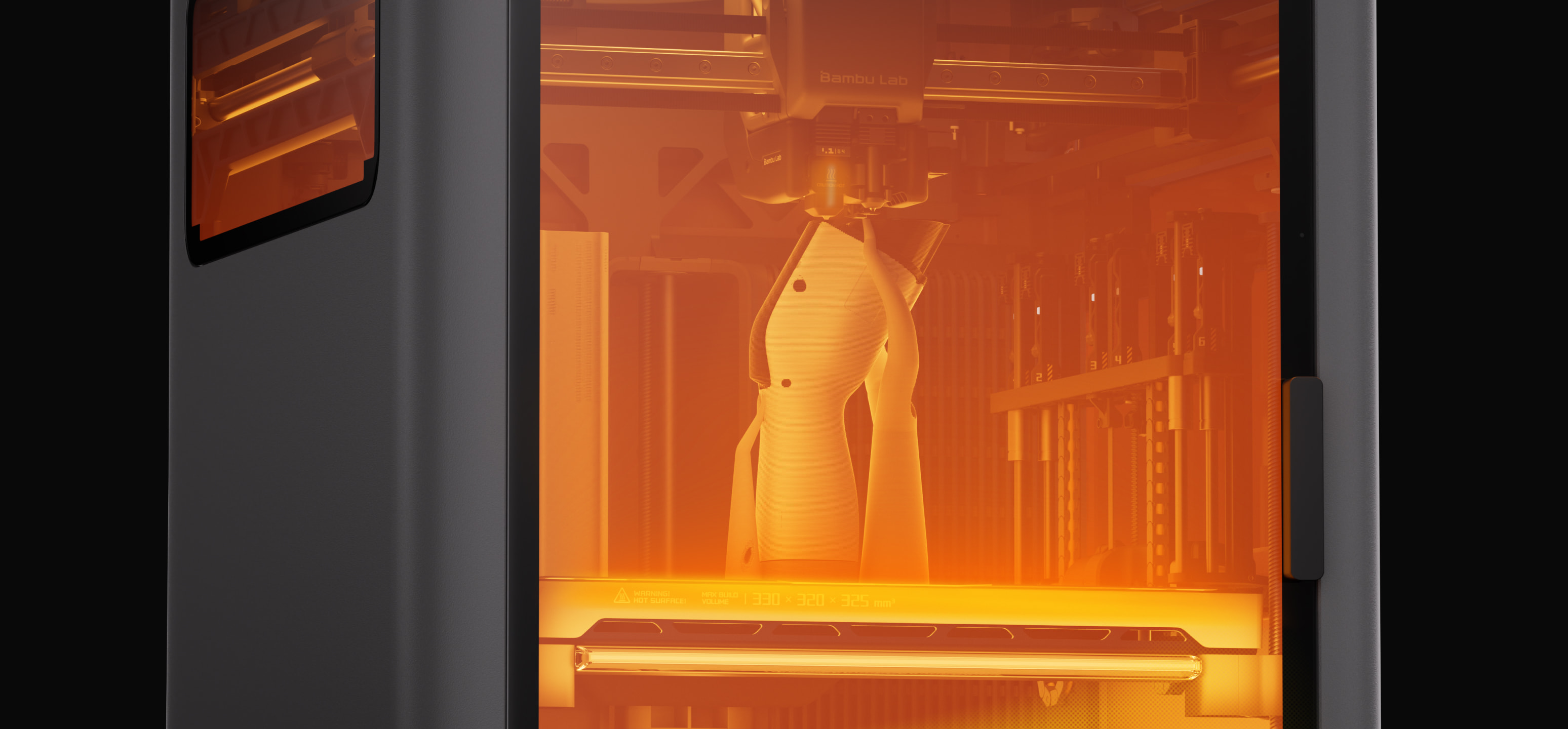

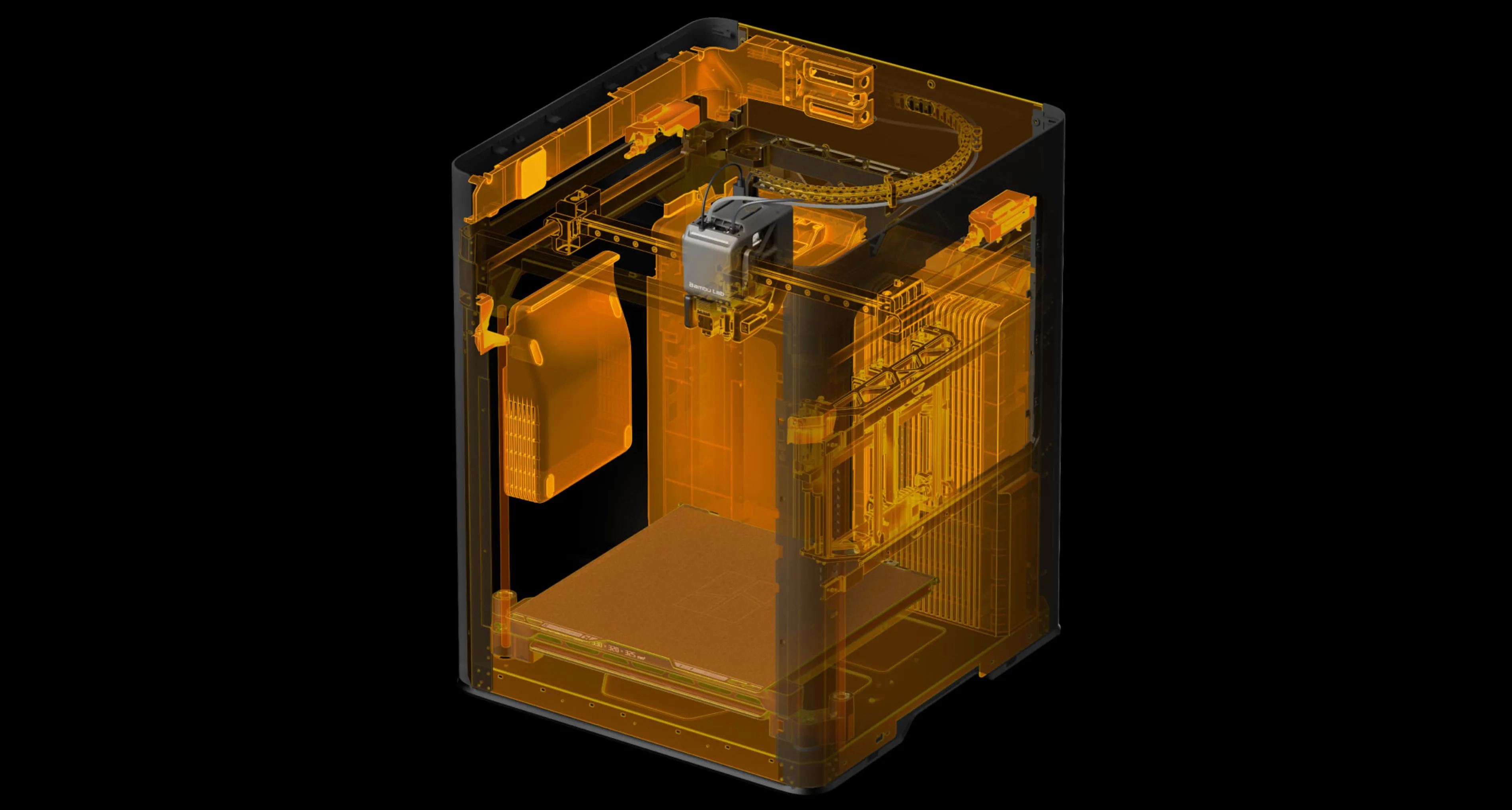

Enclosed for High-Performance Printing

Enclosed for High-Performance PrintingWith its seamless enclosure and adaptive airflow system, the H2C maintains a stable chamber temperature for high-performance materials and filters the air to keep your workspace clean and safe.

-

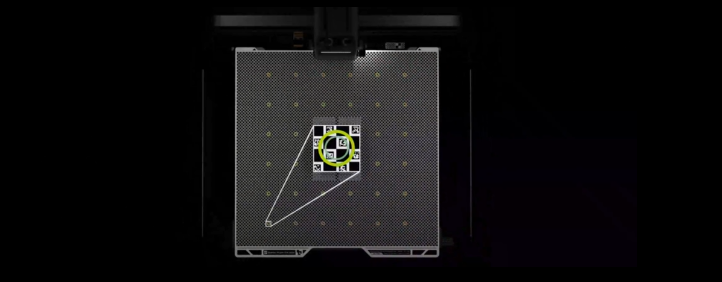

Fully Automatic Nozzle Offset Calibration

Fully Automatic Nozzle Offset CalibrationOur inductive nozzle offset calibration is fully automated — no manual steps, no calibration plates, no extra setup. In just a few minutes, the H2C precisely calibrates nozzle offset to within 25 microns.*

-

Dedicated Hotends for Specific Filaments

Dedicated Hotends for Specific FilamentsThe H2C's Vortek system lets you dedicate one of its six interchangeable hotends to specific filaments — a game-changer for valuable engineering materials.This ensures superior consistency and reliability across prints. Each hotend can even automatically store filament information, so the next time you load that material, it's instantly matched to the correct hotend.

-

-

Better High-Speed Reliability & Real-Time Error Detection.

Better High-Speed Reliability & Real-Time Error Detection.The PMSM servo extruder delivers up to 10 kg of maximum extrusion force—70% more than stepper motor—dramatically improves high-flowrate extrusion stability. Our proprietary servo architecture samples resistance and position at 20 kHz, actively detecting filament grinding and clogs in real time.

-

50 µm Ultra-Fine Motion Accuracy*

50 µm Ultra-Fine Motion Accuracy*With its Vision Encoder, the H2C achieves a distance-independent motion accuracy of less than 50 μm—thinner than human hair. The system automatically compensates for any mechanical drift during calibration, ensuring consistent precision and peak performance over time.*

-

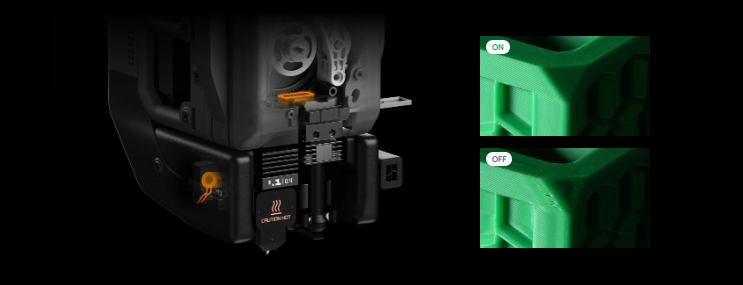

Smooth Surface, Sharp Edges

Smooth Surface, Sharp EdgesThe H2C leverages both the servo motor on the extruder and the high-resolution eddy current sensors on the nozzle to sense extrusion dynamics. This enables precise extrusion control and automatic calibration of Pressure Advance (PA) parameters for each filament, resulting in smoother surfaces and cleaner, sharper edges.

-

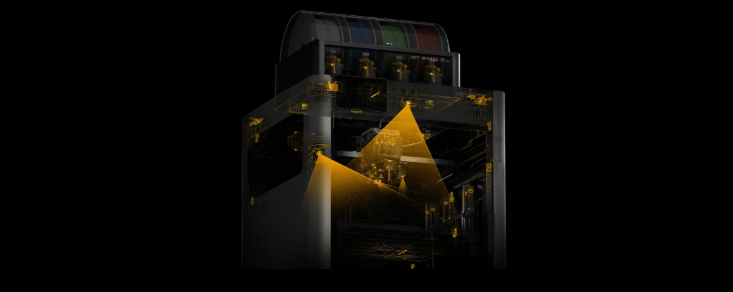

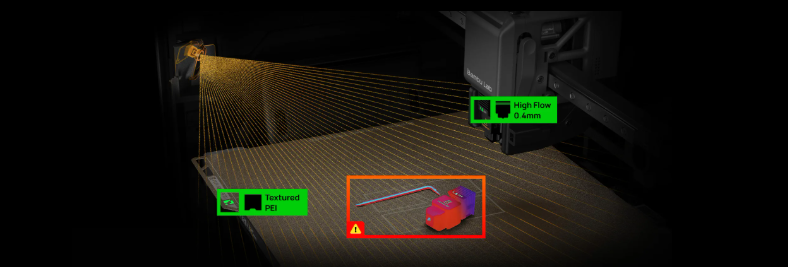

Comprehensive Print Monitoring

Comprehensive Print MonitoringThe H2C is equipped with an array of 59 sensors* and a quad-camera computer vision system, all orchestrated by our proprietary neural algorithm. During printing, this system delivers intelligent, real-time diagnostics that can detect even the most subtle print anomalies as they happen. You don't have to be an expert to solve problems—your printer does the job for you.

-

AI Camera

AI CameraThe H2C features an AI-backed camera system. This intelligent monitoring system continuously tracks extrusion patterns, immediately detecting material accumulation, filament deviations, and extrusion failures. Also runs a pre-flight scan to ensure a safe start.

-

-

-

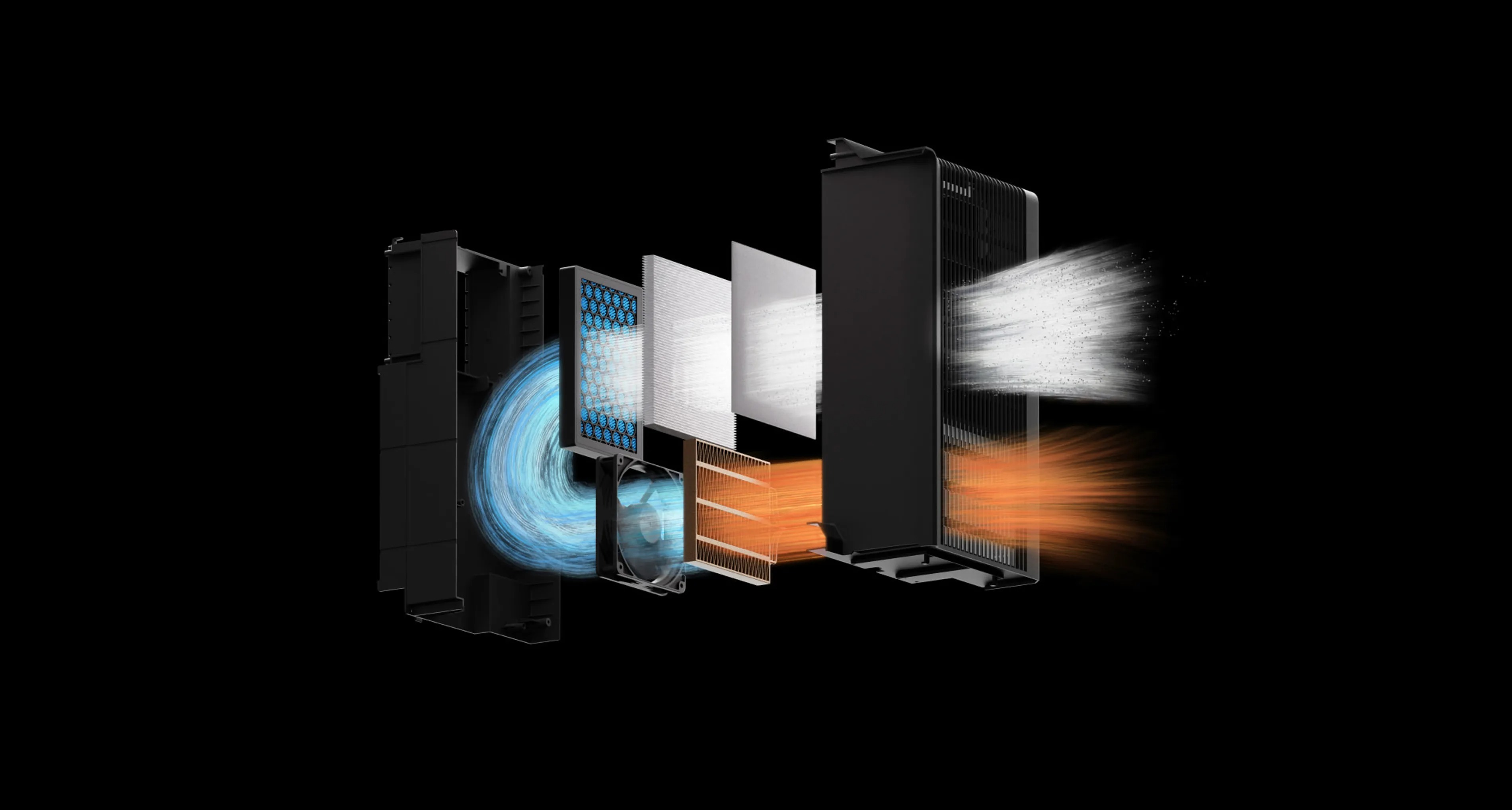

Best-In-Class Air Filtration

Best-In-Class Air FiltrationThe H2C's three-stage filtration system is essential for printing with engineering filaments. This powerful combination of a G3 pre-filter, an H12 HEPA filter, and a coconut shell activated carbon filter effectively minimizes the odors and harmful particulates often released by engineering materials.

-

Fire-Retardant Construction

Fire-Retardant ConstructionThe H2C's chamber is constructed entirely with flame-retardant material, providing robust, passive fire safety protection across the entire enclosure.

-

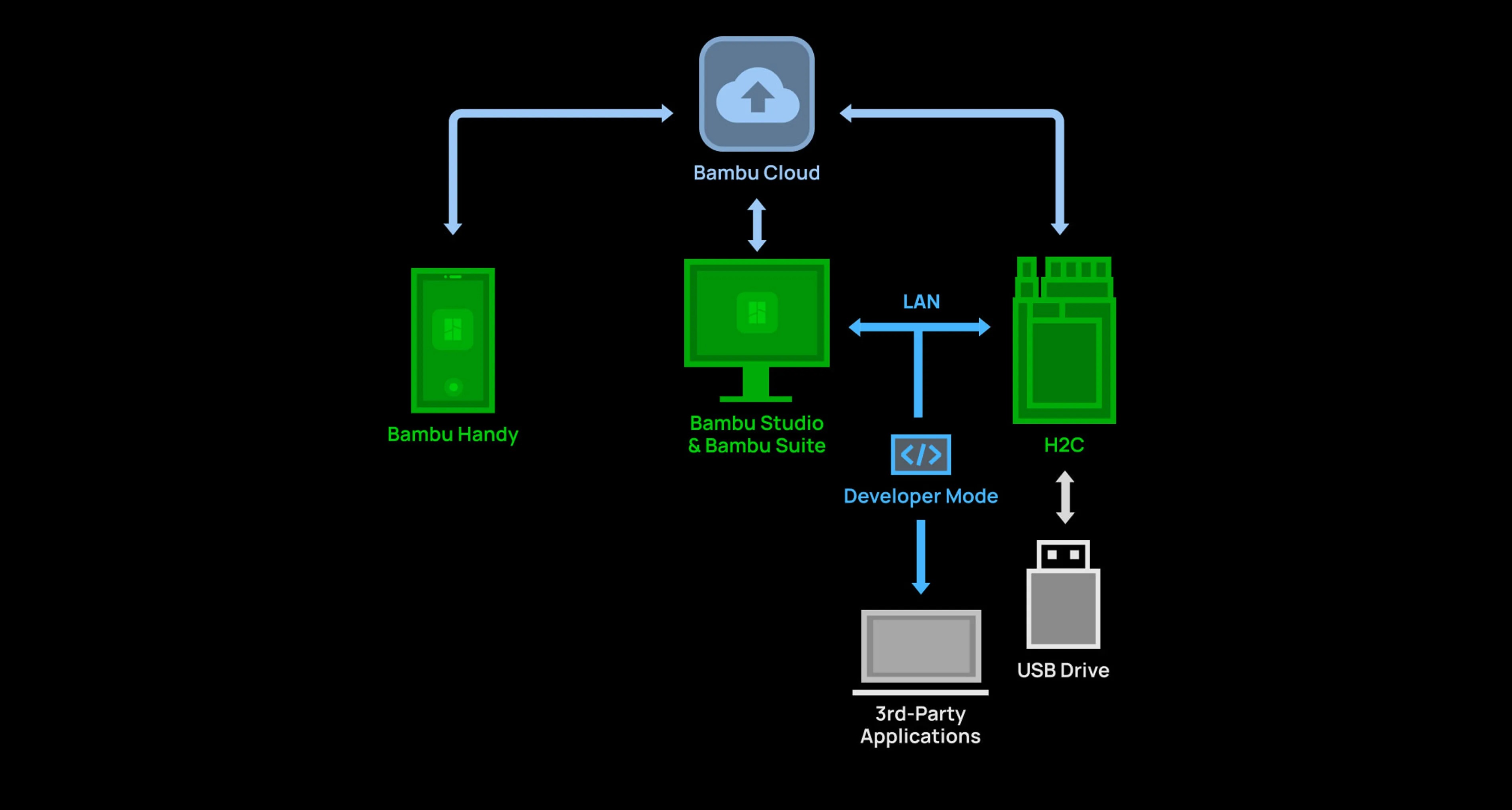

Flexible Network Security & Connectivity

Flexible Network Security & ConnectivityThe H2C offers convenient cloud connectivity for remote control from any device. For security-sensitive applications, it also provides full offline functionality, ensuring complete physical isolation. Users can operate the printer, send files, and update firmware without an internet connection. For advanced users, Developer Mode enables MQTT port access for integrating third-party components and software.*

-

| Build Volume (W*D*H) |

340*320*340 mm³

|

| Chassis | Aluminum, Steel, Plastic and Glass |

|---|---|

| Laser Safety Windows |

Equipped on Laser Edition, normal H2S can upgrade through Laser Upgrade Kit

|

| Air Assist Pump | Equipped on Laser Edition, normal H2S can upgrade through Laser Upgrade Kit |

| Physical Dimensions | 492*514*626 mm³ (Package size: 620*620*755 mm³) |

| Net Weight |

H2S: 30 kg

|

| Hotend | All Metal |

| Extruder Gear | Hardened Steel |

| Nozzle | Hardened Steel |

| Max Nozzle Temperature | 350 °C |

| Included Nozzle Diameter | 0.4 mm |

| Supported Nozzle Diameter | 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm |

|

Filament Cutter

|

Built-in

|

| Filament Diameter | 1.75 mm |

Customer Reviews

of customers recommend this product